The dual-circuit hydraulic brake system from Paul Forrer AG

Both the components and the complete system meet the requirements that came into force in 2016 with the new braking regulations. The following points are fulfilled by the H2L hydraulic dual line brake system according to the required specifications:

- The diagram of the braking system complies with the construction regulations of the Delegated Regulation 2015/68 EU and the directives of FEDRO.

- Automatic emergency braking takes place in the event of:

- Separation of the brake line (for single and two-wire operation)

- Separation of the auxiliary line

- Pressure drop in auxiliary line (e.g. pump failure, motor stalling, etc.). - Automatic, load-dependent brake force control for the corresponding vehicle classes (e.g. transport trailers).

- Multi-stage load adjustment for the corresponding vehicle classes (e.g. towed working machines).

- Brake system design possible for all gross vehicle weight classes.

- Achievement of the required threshold times (brake release speed) of 0.6 seconds is ensured in every weight class and trailer combination (e.g. with pressure transmission) by installing the relay valve.

Temporary coupling (emergency operation) of new trailer to single-wire brake system possible.

The H2L hydraulic dual line brake system is DTC and TÜV certified

In order for new vehicles, e.g. trailer manufacturers, to be allowed to put them into circulation, a so-called homologation (type test) must be carried out in advance. With the certification of our hydraulic 2-conductor brake system by TÜV NORD, homologation with regard to the brake system is ensured.

"TÜV NORD Mobility" expert opinion no. 8115324918

The expert opinion of the TÜV confirms that our hydraulic two-wire brake system is 100% compatible with the construction regulations of Regulation (EU) 2015/68.

DTC Certificate

In addition to TÜV NORD, the conformity of the H2L hydraulic 2-conductor brake system has also been confirmed by the Swiss DTC Dynamic Test Center. The DTC certificate must be presented for individual approvals in Switzerland.

Practical brake test with a dual line brake

The H2L hydraulic two-wire braking system has exceeded all safety requirements under tough operating conditions.

A group of well-known manufacturer representatives (vehicles and axles), as well as TÜV NORD Mobilität (Technical Service for Brake Systems in accordance with EU Regulation 167/2013), carried out joint driving and braking tests with the hydraulic two-wire braking system in spring 2018 on the premises of the Dynamic Test Center DTC in Vauffelin (CH) with the support of the Bern University of Applied Sciences (BFH) in order to test its practical suitability.

Initial situation

For these tests, Fliegl Agrartechnik GmbH provided two 18-tonne turntable trailers, which were loaded with their permissible total weight for the test runs. The axles were checked and run in beforehand by the German axle manufacturer BPW, as is usually done for type tests.

For the driving tests, the known behaviour of agricultural trailer combinations (tractor with one or two trailers) with two-line air brakes was used as a benchmark. In extensive test drives, measurements were taken in different driving situations to check the conformity, functionality and braking behaviour of the system.

Brief documentation on the tests carried out

The H2L hydraulic dual line braking system was able to convince all along the line in the tests carried out

The results achieved:

- The tests carried out by "TÜV NORD Mobilität" according to DV 2015/68 EU have been fulfilled and could be concluded positively.

- The driving and braking tests with the active 2-line hydraulic braking system H2L, with one and with two trailers in the train, showed a balanced (braking) behaviour. This applies to both the loaded condition and the unloaded condition of the trailers.

- The measured decelerations of the individual vehicles in the train were judged to be absolutely uniform.

- With regard to the response and release behaviour of the trailer brakes, no recognisable deviating behaviour - from trailers of the same type equipped with compressed air brakes - could be detected.

- All technical specifications were met or even exceeded by the test vehicles without any reservations.

Following these successful tests, homologations and type tests are now being carried out by European manufacturers on various trailers and equipment with hydraulic brakes. Thus, due to the approaching deadlines, a practical two-wire solution for the higher safety requirements can be offered to the market.

The "Brakes" Competence Centre at Paul Forrer AG will be happy to provide detailed information and technical advice.

Egg building schemes

The installation diagrams for the various trailer types are available here.

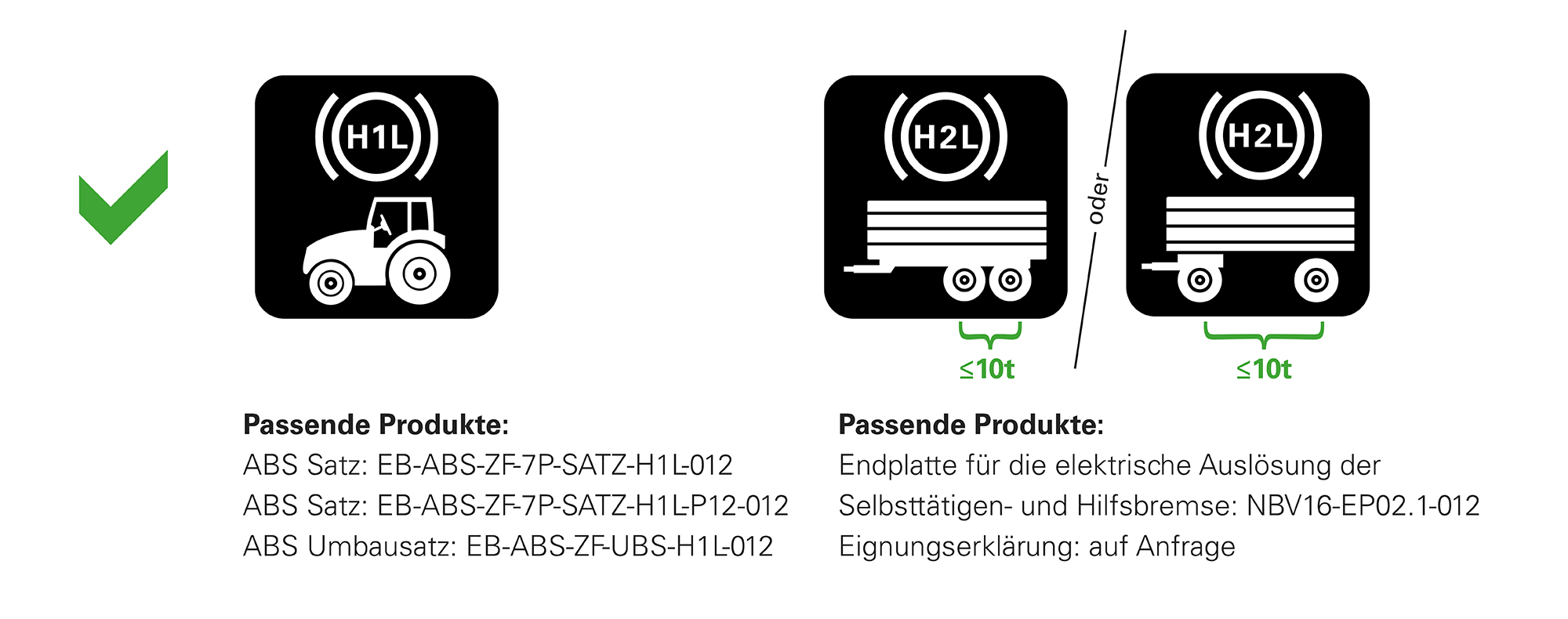

Compatibility of hydraulic H1L brakes with product overview of the different combinations

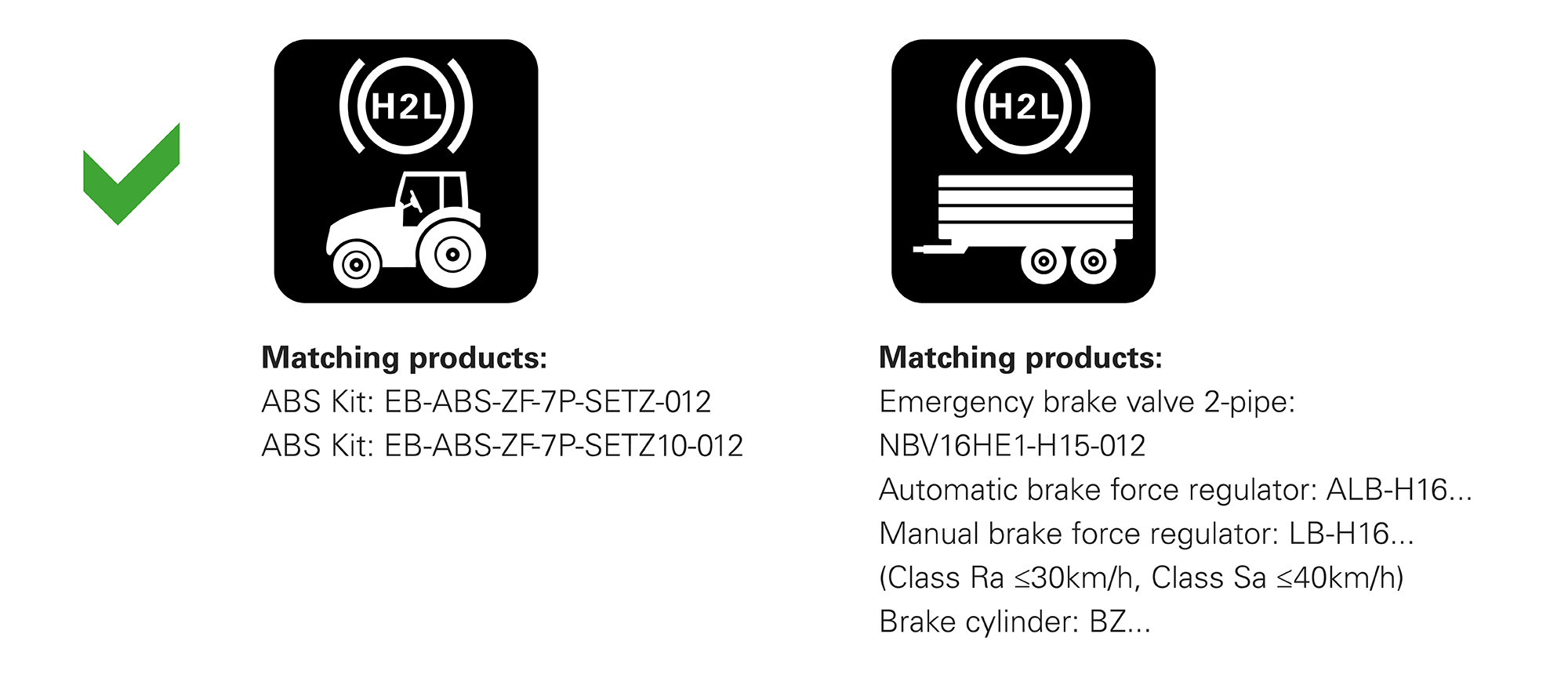

Combination of H2L tractor and H2L trailer

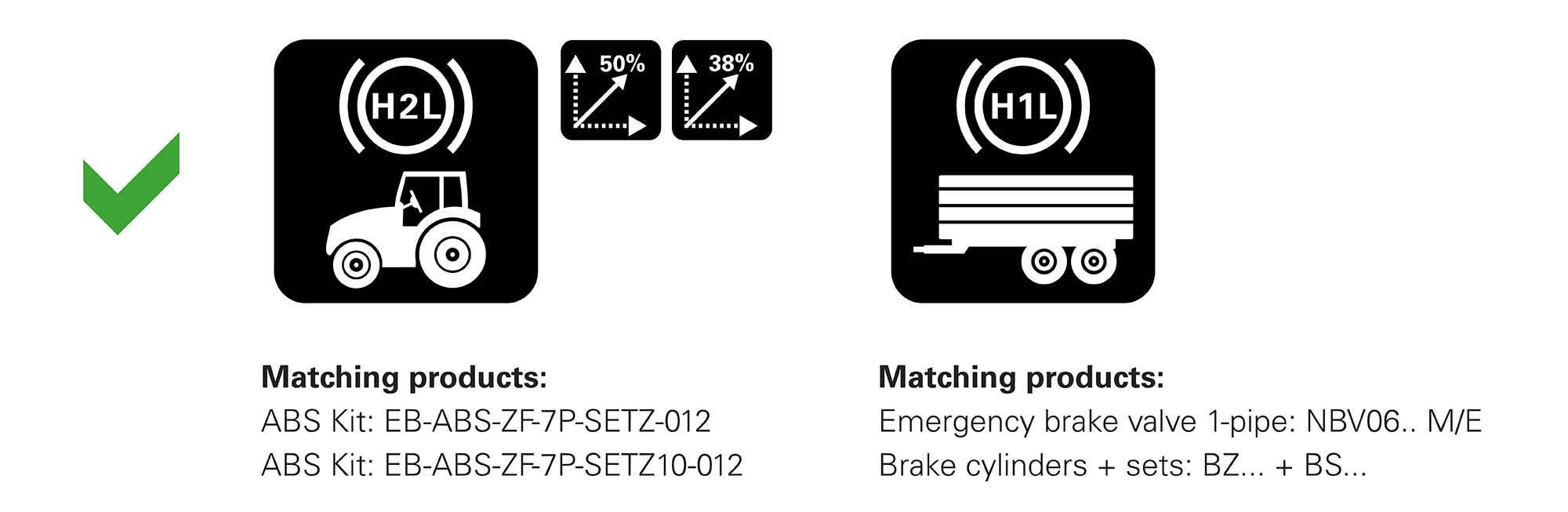

Combination of H2L tractor with detection and H1L trailer

Combination of H1L tractor and H2L trailer / ASTRA directive of 28 May 2020